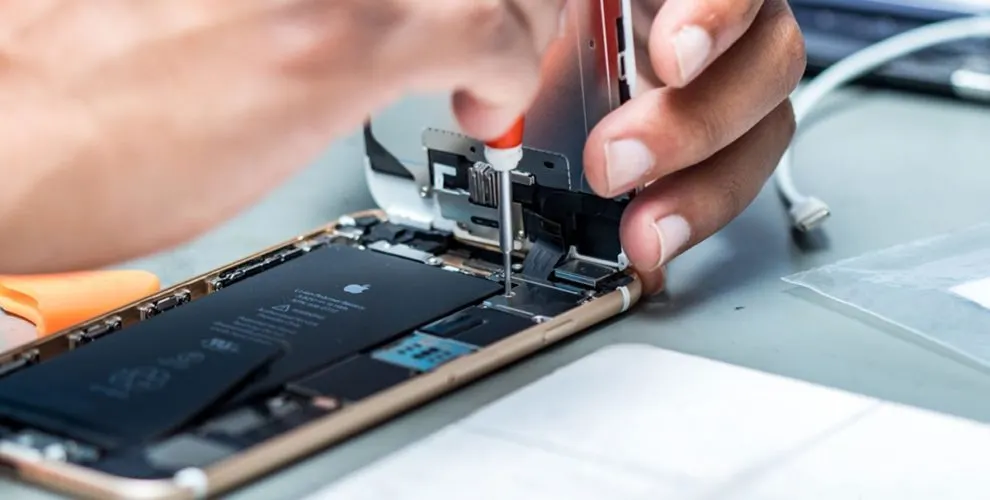

When it comes to mobile repairing, one of the most important yet underrated tools is the mobile repair screwdriver. Whether you are a beginner trying to open your old smartphone at home or an aspiring technician who wants to make a career in mobile repair, using a screwdriver correctly is the first step toward success.

But here’s the truth: most people don’t realize how a small mistake with a screwdriver can cause permanent damage to a mobile device. I’ve seen countless students at Vaishno Mobile’s training center in Delhi make the same mistakes before they learn the right techniques.

This blog is written to help you avoid those mistakes, improve your repair skills, and—if you’re serious about mastering this profession—show you how you can get trained properly.

So let’s dive deep into the 5 common mistakes people make when using a mobile repair screwdriver, along with solutions, professional insights, and comparisons that will help you grow in your repair journey.

Why Mobile Repair Screwdrivers Are So Important

A mobile repair screwdriver may look like a simple tool, but in reality, it’s the backbone of every successful mobile repair. Mobile devices are built with tiny, specialized screws—often different from regular household screws. That’s why professionals use precision screwdrivers with different heads like Torx, Phillips, Tri-Wing, and Pentalobe.

Using the wrong screwdriver or applying the wrong technique doesn’t just waste your time; it can:

-

Strip the screw head

-

Crack the phone’s body

-

Cause internal damage to sensitive parts like circuits and connectors

-

Lead to expensive mistakes

Think of a screwdriver as a surgeon’s scalpel: you cannot afford to mishandle it.

Mistake 1: Using the Wrong Screwdriver Size

This is the most common mistake beginners make. Mobile phones don’t use standard screws; each brand and model may have unique sizes. For example, an iPhone uses Pentalobe screws, while some Android devices use Phillips or Torx screws.

Why it’s a problem

-

A wrong-sized screwdriver slips, damaging the screw head.

-

Stripped screws become impossible to remove without advanced tools.

-

Applying force with the wrong tool can bend the frame or break the glass back.

Correct Approach

-

Always check the screw size and type before you start.

-

Invest in a screwdriver kit that includes multiple heads.

-

Organize screws properly when disassembling to avoid mixing them up.

👉 Pro Tip: At Vaishno Mobile, we train our students to identify screw types by sight—this saves time and prevents costly errors.

Mistake 2: Applying Too Much Force

Another beginner mistake is to assume that tighter screws need stronger force. But smartphones are delicate machines. Applying too much pressure can:

-

Damage the screwdriver tip

-

Crack the mobile frame

-

Injure your own hand

Correct Approach

-

Use light, steady pressure while turning.

-

Always use a screwdriver with a rotating cap for better grip and control.

-

If a screw is stuck, use tools like a heat gun or screw extractor instead of applying brute force.

Mistake 3: Not Using Magnetic Screwdrivers

If you’ve ever opened a phone, you know how tiny those screws are. Losing one screw can affect the phone’s durability and assembly.

Why it’s a problem

-

Small screws fall inside the device, risking short circuits.

-

Lost screws make the device loose and unstable.

Correct Approach

-

Use magnetic screwdrivers so screws stick to the tip.

-

Always work on a clean, flat surface with a magnetic mat.

-

Keep screws organized using labeled trays.

Mistake 4: Ignoring Screw Placement

Every screw in a smartphone has a specific role. Even if two screws look the same, their length and diameter may differ slightly. Many beginners mix up screws during reassembly.

Why it’s a problem

-

Wrong screws can pierce sensitive parts like motherboards.

-

A slightly longer screw can damage display panels.

-

Misplaced screws cause misalignment in the body frame.

Correct Approach

-

Place screws in order on a magnetic pad.

-

Take reference photos while disassembling.

-

Use screw organizers labeled according to device sections.

👉 At Vaishno Mobile, our trainers emphasize professional-level organization skills, which help students save time and avoid mistakes.

Mistake 5: Using Low-Quality Screwdrivers

Cheap screwdriver kits may look attractive, but they wear out quickly and damage screws. Many beginners buy them to save money but end up causing more losses.

Why it’s a problem

-

Poor grip and unstable tips strip screws.

-

Low-quality material bends under pressure.

-

Screwdriver tips rust, making them useless.

Correct Approach

-

Always invest in professional-grade screwdriver kits.

-

Look for features like anti-rust coating, ergonomic handle, and durable steel tips.

-

Treat your tools as an investment in your career.

Comparison Table: Low-Quality vs. Professional Screwdriver Kits

| Feature | Low-Quality Screwdrivers | Professional Screwdrivers |

|---|---|---|

| Material | Soft metal, rusts easily | Hardened steel, rust-resistant |

| Grip | Slippery plastic handle | Ergonomic, non-slip design |

| Durability | Wears out in weeks | Lasts for years |

| Accuracy | Tips lose shape quickly | Precision-engineered tips |

| Cost | Cheap upfront | Cost-effective in the long run |

👉 Lesson: Always choose quality over cost when building your mobile repair toolkit.

The Right Way to Use a Mobile Repair Screwdriver

To avoid all these mistakes, here’s a step-by-step guide to using a mobile repair screwdriver correctly:

-

Identify screw type (Pentalobe, Phillips, Torx, etc.)

-

Select the correct screwdriver head

-

Hold the device firmly on a flat surface

-

Apply light, controlled pressure

-

Rotate gently while keeping the screwdriver vertical

-

Store screws carefully in sequence

-

Reassemble with patience and precision

When done right, this process ensures safety for both the device and the repair technician.

Why Learning Proper Techniques Is Essential

Many people try to learn mobile repairing on their own through YouTube videos. While this may work for simple repairs, professional-level skills require structured training. Without the right knowledge:

-

You risk damaging devices beyond repair

-

You won’t be able to handle advanced models

-

You may lack confidence in real-world scenarios

That’s why institutes like Vaishno Mobile in Delhi offer specialized mobile repairing courses. These courses don’t just teach you how to use tools; they also cover circuit understanding, fault diagnosis, soldering, IC replacement, and advanced repair methods.

Final Thoughts

Using a mobile repair screwdriver may sound simple, but in reality, it requires skill, patience, and the right knowledge. By avoiding the 5 common mistakes—wrong size, too much force, non-magnetic tools, ignoring screw placement, and low-quality kits—you can save time, protect devices, and grow your repair career.

At Vaishno Mobile, we don’t just teach tools—we prepare you for a successful future in the mobile repairing industry. If you are passionate about technology and want to build a profitable career, this is your chance.

👉 Enroll in our Mobile Repairing Course in Delhi today and master every tool, technique, and skill you need to become a professional mobile repair expert.

📞 Call us now or visit our training center to start your journey toward becoming a certified mobile repair technician.

FAQs

1. Can I use a normal screwdriver for mobile repairing?

No. Normal screwdrivers are too big and rough for smartphones. Always use precision mobile screwdrivers designed for electronics.

2. Why do some screwdrivers have rotating caps?

Rotating caps allow you to turn the screwdriver smoothly with one hand, giving you more control and reducing the risk of slipping.

3. Is a magnetic screwdriver safe for mobiles?

Yes, magnetic screwdrivers are safe and recommended. The magnetic strength is too low to damage phone components.

4. How can I avoid losing screws while repairing?

Work on a magnetic mat or screw organizer. Take photos while disassembling to remember placement.

5. Do I need professional training to repair mobiles?

Yes, if you want to work professionally. Training helps you avoid mistakes, build confidence, and handle complex repairs.

Leave a Reply