Embarking on a journey to become a skilled mobile technician is an exciting prospect, especially in a bustling area like Ghaziabad. As you delve into the intricate world of smartphones, you’ll discover that success often lies in mastering the small details and understanding the essential tools of the trade. One of the most crucial yet often overlooked components in a technician’s toolkit is Mobile Repairing Paste. This humble substance is fundamental to performing precise, durable, and effective repairs on a device’s motherboard. At our premier mobile repairing institute in Ghaziabad, we emphasize that a deep understanding of materials like this paste is what separates an amateur from a professional.

This guide is designed to demystify the world of mobile repairing pastes. We will explore what they are, the different types available, and why they are absolutely indispensable for anyone serious about a career in mobile repair. Think of this as your foundational lesson before you even step into the classroom. We’ll break down the science behind soldering and explain how the right paste can make the difference between a successful repair and a permanently damaged device. For aspiring technicians in Ghaziabad, mastering these core concepts is the first step toward a rewarding and profitable career.

What Exactly is Mobile Repairing Paste?

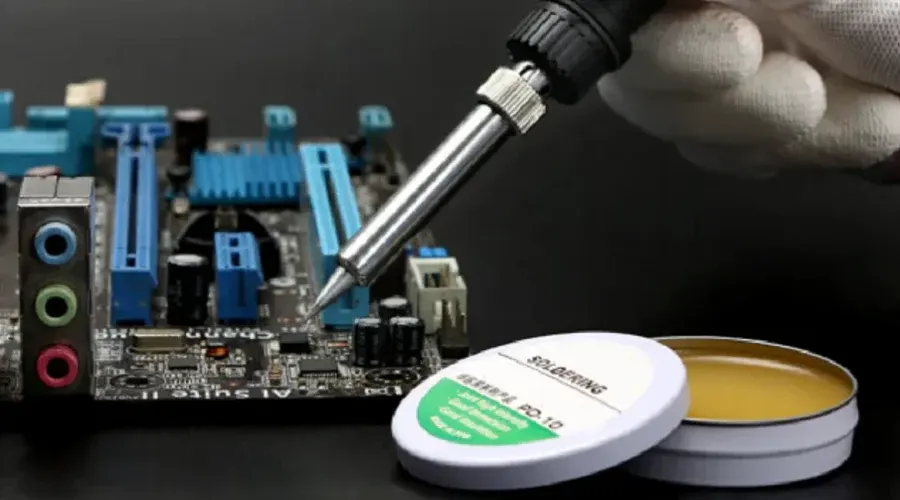

At its core, mobile repairing paste is a type of solder flux. It’s a chemical agent used in the soldering process to prepare and clean metal surfaces, ensuring a strong and reliable solder joint. When you’re working on a smartphone’s printed circuit board (PCB), you’re dealing with incredibly small components and delicate connections. Without a high-quality flux, creating these connections would be nearly impossible.

The Three Main Functions of Flux (Repairing Paste):

- Cleaning: The paste removes oxides and other impurities from the surfaces of the components and the PCB pads. Metal surfaces naturally oxidize when exposed to air, and this oxide layer prevents solder from bonding properly. The flux chemically cleans these surfaces when heated.

- Improving Wetting: “Wetting” is the term used to describe how well molten solder flows and adheres to a surface. The paste reduces the surface tension of the molten solder, allowing it to spread evenly and form a solid, uniform connection.

- Preventing Re-oxidation: As you heat the components and the board to melt the solder, the flux forms a protective barrier over the area, preventing the hot metal from re-oxidizing. This ensures the integrity of the solder joint as it cools and solidifies.

In mobile repair, this paste is often a mixture of flux and tiny spheres of solder metal, creating a substance with a paste-like consistency. This combination allows for precise application, which is critical when working with microscopic components on a modern smartphone motherboard.

Different Types of Mobile Repairing Paste and Their Uses

Not all repairing pastes are created equal. Different repair scenarios call for different types of flux. As a future technician, you must know which one to use and when. The pastes are generally categorized based on their composition and cleaning requirements.

1. Rosin-Based Flux

This is one of the most common types of flux used in electronics. It is derived from the resin of pine trees.

- Rosin (R): The mildest form, it requires very clean surfaces to be effective. It is non-corrosive and non-conductive, making it a safe choice for beginners.

- Rosin Mildly Activated (RMA): This is the go-to choice for most mobile repair professionals. It contains a small amount of activator that boosts its cleaning power, making it more effective at removing oxides. It is still relatively non-corrosive, but cleaning the residue after the repair is good practice.

- Rosin Activated (RA): This is the most aggressive type of rosin flux. Its powerful activators can clean heavily oxidized surfaces. However, it is highly corrosive and conductive, so the residue must be thoroughly cleaned after soldering to prevent long-term damage to the PCB.

For students at our institute in Ghaziabad, we start with RMA flux as it offers the best balance of performance and safety for most mobile repair tasks.

2. No-Clean Flux

As the name suggests, “No-Clean” flux is designed so that its residue does not need to be removed after the soldering process. The residue is non-corrosive and non-conductive, so leaving it on the board won’t cause issues.

- Advantages: This saves time and reduces the risk of damaging the board with harsh cleaning chemicals. It’s perfect for quick repairs and for working on components that are difficult to access for cleaning.

- Considerations: While it’s called “no-clean,” some technicians prefer to clean the residue for aesthetic reasons or to allow for easier inspection of the solder joints. The sticky residue can also attract dust and debris over time.

3. Water-Soluble Flux

This is a powerful, highly active flux that can handle even difficult soldering jobs. Its primary advantage is that the residue can be easily cleaned away with simple de-ionized water.

- Advantages: Excellent cleaning power and easy cleanup without the need for chemical solvents.

- Disadvantages: The flux and its residues are highly corrosive and conductive before cleaning. It is absolutely critical that all residue is washed away, as any remaining flux can quickly corrode component leads and destroy the circuit board. This type is generally reserved for advanced, industrial applications rather than typical phone repairs.

Why is Paste Essential for IC Reballing and Component Replacement?

One of the most advanced and common repairs you’ll learn is Integrated Circuit (IC) reballing. Smartphone CPUs, memory chips, and power management ICs are connected to the motherboard using a grid of tiny solder balls known as a Ball Grid Array (BGA). When these connections fail, the chip needs to be removed, the old solder cleaned off, and new solder balls applied—a process called “reballing.”

Mobile repairing paste is the hero of this process.

- IC Removal: Before heating the chip to remove it, flux is applied around its edges. The flux helps distribute heat evenly from the hot air gun and facilitates the melting of all the solder balls at the same time, allowing for safe removal without damaging the board or the chip.

- Pad Cleaning: After the IC is removed, the pads on the motherboard are covered in old, uneven solder. Flux is applied to these pads, and a soldering iron with a wick is used to clean them. The flux helps the wick absorb the old solder, leaving behind clean, flat pads.

- Reballing the IC: The new solder balls are applied to the IC using a stencil. Solder paste (a mix of flux and solder particles) is spread over the stencil. When the stencil is removed, a perfect pattern of paste dots is left on the IC’s pads.

- IC Reattachment: A final, thin layer of flux is applied to the motherboard pads. The reballed IC is carefully aligned and placed on the board. When heat is applied, the flux cleans the surfaces and ensures the new solder balls melt and bond perfectly to the pads, creating a like-new connection.

Without the correct application of the right mobile repairing paste, this intricate repair would be impossible.

Choosing the Right Mobile Repairing Paste: A Technician’s Guide

With so many options on the market, how do you choose the right paste? Here are a few factors to consider:

- Tackiness: The paste should be tacky enough to hold components in place before soldering but not so sticky that it makes positioning them difficult.

- Viscosity: This refers to the thickness of the paste. A good paste should be easy to dispense from a syringe and spread evenly without running all over the board.

- Activity Level: For general-purpose mobile repair, an RMA (Rosin Mildly Activated) or a good quality No-Clean flux is usually the best choice. They provide enough cleaning power without being overly corrosive.

- Brand Reputation: Not all pastes are created equal. Brands like Amtech, Mechanic, and Relife are well-regarded in the repair community for their consistent quality. In our courses, we introduce students to the industry-standard tools and materials they will use in their professional careers.

Common Mistakes to Avoid When Using Repairing Paste

Using flux correctly is a skill. Here are some common pitfalls that beginners often fall into, which we train our students in Ghaziabad to avoid:

- Using Too Much Paste: More is not better. Excessive paste can bubble up when heated, causing components to shift. It also leaves a larger residue that can be difficult to clean and may hide bad solder joints.

- Using Too Little Paste: Insufficient paste won’t clean the surfaces properly, leading to poor wetting, solder bridges (short circuits between pins), and weak, unreliable joints.

- Overheating the Flux: Heating the paste for too long or at too high a temperature can “burn” it, depleting its chemical activators before it can do its job. This leaves behind a dark, difficult-to-clean residue and results in a poor solder connection.

- Not Cleaning Corrosive Flux: The number one rule when using an active (RA) or water-soluble flux is to clean the board thoroughly afterward. Failing to do so is a guaranteed way to cause device failure down the line due to corrosion.

Mastering these nuances is a key part of the hands-on training we provide. Understanding theory is one thing, but developing the practical skill to apply it is what truly makes a great technician.

Take the Next Step in Your Mobile Repairing Career

The world of mobile repair is deep, detailed, and incredibly rewarding. Understanding the function and application of something as basic as Mobile Repairing Paste is a perfect example of the foundational knowledge required for success. It’s this attention to detail and commitment to quality that turns a simple hobby into a professional skill set. If you are passionate about technology and looking for a hands-on career, our mobile repairing institute in Ghaziabad is the perfect place to start your journey and build a prosperous future.

Are you ready to move beyond theory and gain the practical, expert-led training you need to become a professional mobile technician?

Enroll in our comprehensive mobile repairing course in Ghaziabad today! We provide the hands-on training, expert guidance, and industry-standard tools you need to build a successful career. Call us or visit our institute to learn more and secure your spot!

Leave a Reply